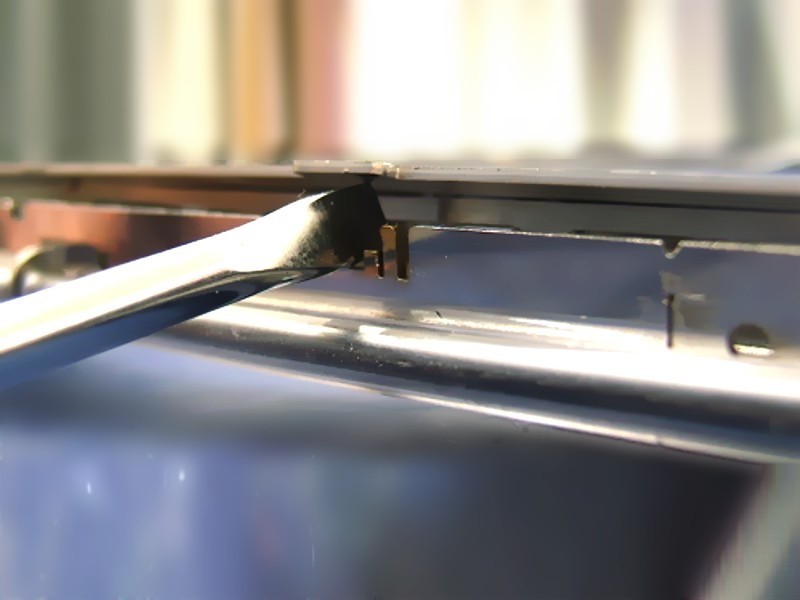

This version has everything you need for an application on a printing press. Simple, compact, robust, with a pedestal that can easily be moved from one machine to another. Programming takes place easily, on the control unit with a tactile membrane and a new microprocessor. In the standard configuration it is supplied a pulse connection cable that normally is connected to the printing press copy counter but can also be connected to dedicated boards or sensors or devices set to this purpose. As an alternative, can be delivered a special optional photocell designed to count sheets out of printing machines counting up to 25,000 sheets / hour. If necessary we can supply a wide range of sensors and accessories for every need.

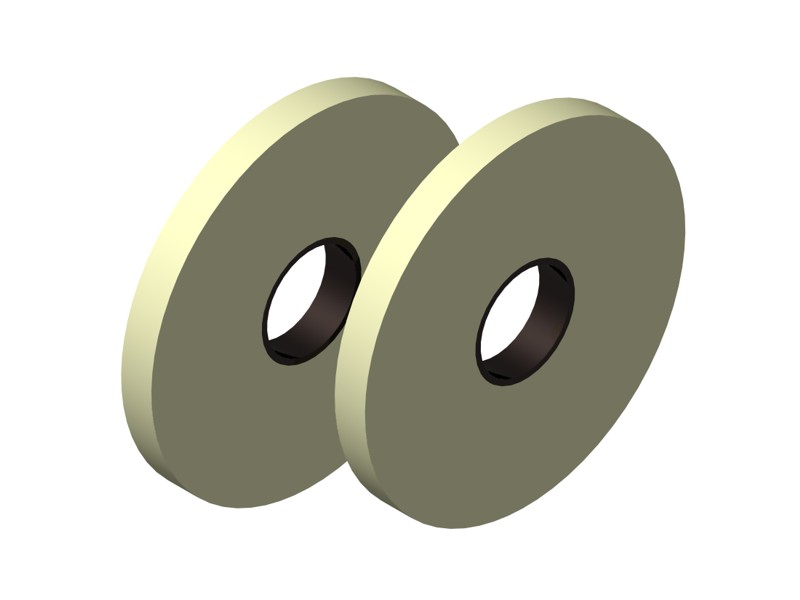

Rolls with 80 GSM tape

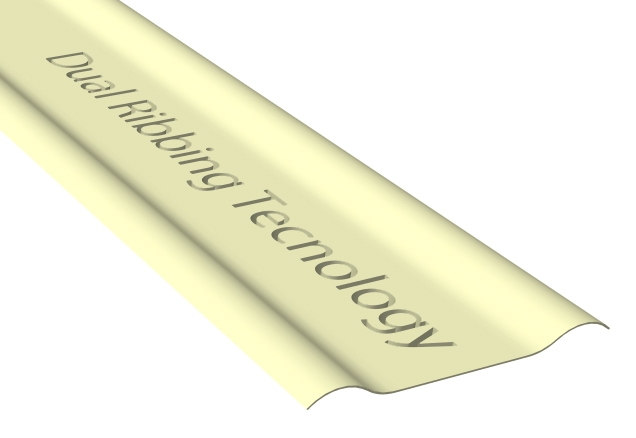

Dual Ribbing technology

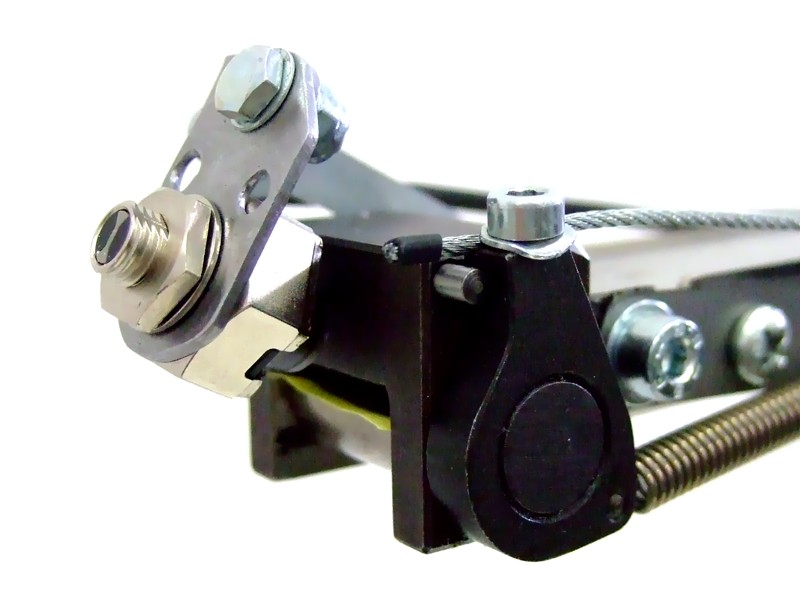

Control unit for "Tab-in Counter"

Flexibility

Tempered steel structure reduces blade wear.

Adjustable support

| model | tab-in |

| Max sheets per tabs programming | 9 999 |

|---|---|

| Counting No. of pack and total sheets | 999 - 999.999 |

| Copy subtraction button | X |

| Accurate counting | X |

| Adjustment of cutting delay and tape length | X |

| Special photocell for printing machine | Optional |

| Dustproof membrane keyboard | X |

| Standard tape guide length | 500 mm |

| Dual ribbing technology | X |

| 80GSM tape rolls | 200 MT |

| Pedestal | Optional |

| Power supply | 230 V 100W. |

| Weight without pedestal | 12 kg |

By clicking on “Accept” you consent to the storage of cookies on your device. Cookies are stored in order to properly provide the services, and for statistical or advertising purposes. More information on how we use cookies and how to manage them can be found in our Cookies Policy.